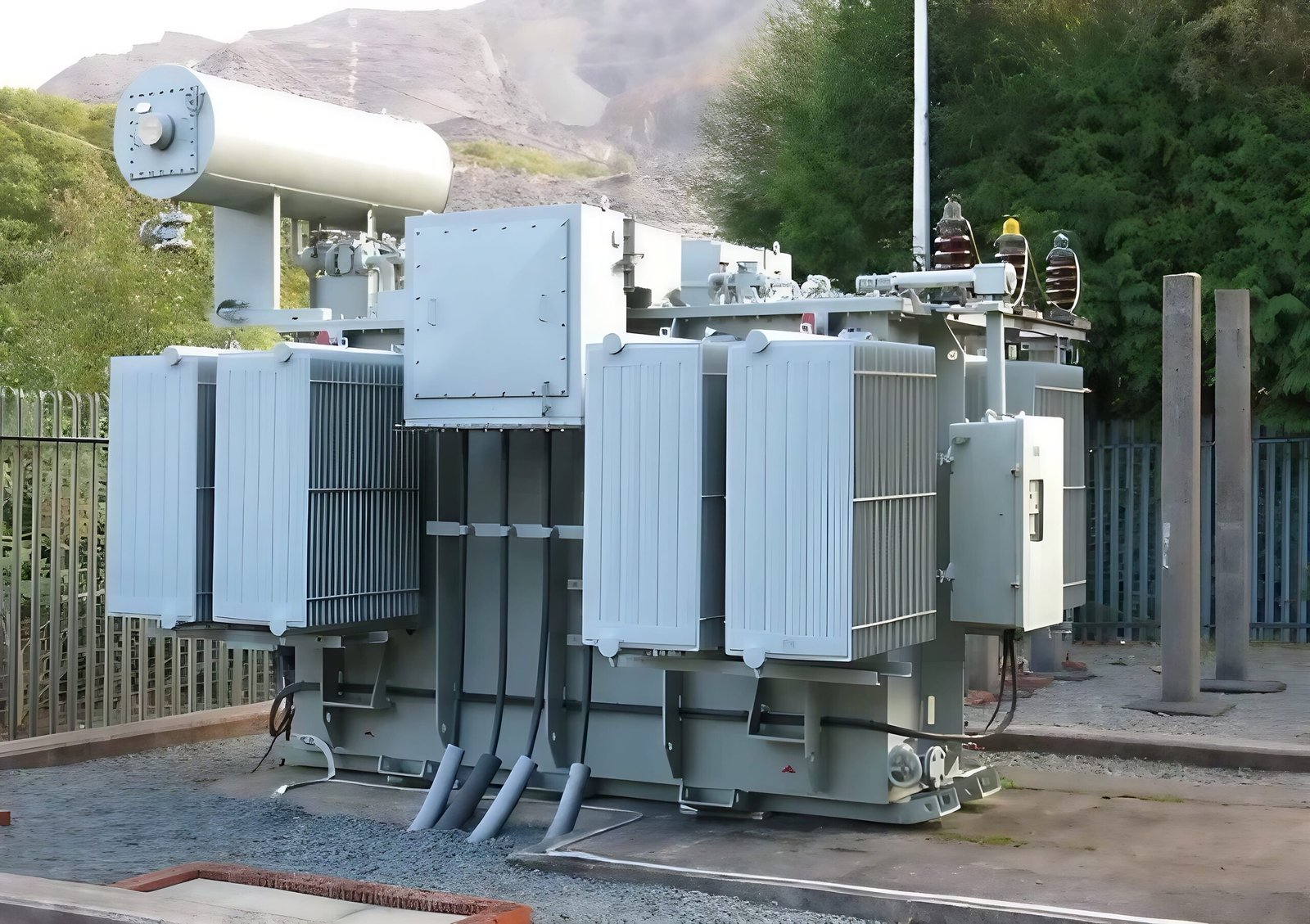

Transformer installation in substations is a critical process that directly impacts the reliability and efficiency of electrical power systems. Improper installation can lead to costly failures, operational downtime, and safety hazards. For businesses and utilities aiming for long-term performance, following best practices during transformer installation is essential. Manikaran Enterprises, a trusted name in the industry, emphasizes these practices to ensure robust and dependable electrical infrastructure.

Why Proper Transformer Installation Matters

Transformers serve as vital components in substations, facilitating voltage regulation and power distribution. Any installation flaw can lead to insulation failure, overheating, mechanical damage, or electrical faults, potentially resulting in outages and expensive repairs. Proper installation not only protects the transformer but also ensures the overall substation operates smoothly, enhancing grid stability and safety.

Best Practices for Transformer Installation in Substations

1. Pre-Installation Inspection and Planning

Before installation begins, conduct a comprehensive inspection of the transformer and the site. Check for physical damages, verify technical specifications, and ensure that the foundation and supports meet design requirements. A detailed plan that covers lifting, positioning, and connection processes helps prevent delays and mistakes.

2. Adequate Handling and Transportation

Transformers are delicate equipment that require careful handling. Use appropriate lifting equipment and follow manufacturer guidelines during transportation to avoid mechanical shocks or contamination. Any damage during transit can compromise the transformer’s integrity and performance.

3. Proper Foundation and Grounding

The foundation must be level, sturdy, and designed to handle the transformer’s weight and vibrations. Adequate grounding is critical for safety and operational reliability. Grounding systems protect personnel and equipment from electrical faults and ensure effective dissipation of fault currents.

4. Correct Positioning and Alignment

Accurate placement and alignment prevent mechanical stress and facilitate efficient cooling. Misalignment can cause premature wear, insulation damage, and reduce the transformer’s lifespan. Use precise measuring tools and follow the layout plans meticulously.

5. Secure Electrical Connections

All electrical connections, including high voltage, low voltage, and neutral terminals, should be tight and corrosion-free. Loose connections generate heat and can lead to arcing or equipment failure. Inspect and torque all connections according to manufacturer specifications.

6. Effective Cooling and Ventilation

Transformers generate heat during operation; thus, ensuring proper cooling is vital. Maintain clearance around the transformer for adequate airflow and use cooling systems as recommended. Overheating accelerates insulation degradation and can trigger shutdowns.

7. Thorough Testing and Commissioning

Before energizing the transformer, conduct rigorous tests such as insulation resistance, turns ratio, and oil quality assessments. These tests confirm that installation is correct and the transformer is ready for safe operation. Commissioning should follow standardized procedures to verify performance under load.

8. Documentation and Maintenance Planning

Keep detailed records of installation steps, test results, and equipment data. Proper documentation supports future maintenance and troubleshooting. Establishing a preventive maintenance schedule helps identify issues early and prolongs transformer life.

Manikaran Enterprises: Your Partner for Transformer Installation and Reliability

For organizations seeking expert support, Transformer Installation and Commissioning Services in India provided by Manikaran Enterprises offer reliable solutions. With extensive experience and a commitment to quality, Manikaran Enterprises ensures every transformer installation adheres to industry best practices, minimizing risks and maximizing uptime.

As a Top Electrical Solution Company in Rajasthan, Manikaran Enterprises combines technical expertise with advanced tools to deliver superior installation services tailored to your substation needs. Their dedicated team understands the critical nature of transformer installations and works closely with clients to ensure seamless project execution.

Conclusion

Avoiding failures in transformer installation is fundamental for the dependable operation of electrical substations. By adhering to best practices such as careful planning, precise handling, proper grounding, secure connections, and comprehensive testing, organizations can safeguard their investments and maintain continuous power supply.

Choosing a professional service provider like Manikaran Enterprises guarantees expert execution and ongoing support, ensuring your electrical infrastructure remains robust and efficient. For reliable Transformer Installation and Commissioning Services in India and trusted solutions from a Top Electrical Solution Company in Rajasthan, Manikaran Enterprises stands out as the partner you can rely on.