Electrical connectors play a crucial role in ensuring the proper functioning and safety of electrical systems. They serve as the link between various components in power systems, ensuring smooth and secure electrical transmission. However, the quality of these connectors is paramount in preventing electrical failures and hazards. In this article, we will explore how high-quality connectors can make all the difference in preventing electrical disasters.

The Role of Connectors in Electrical Systems

Electrical connectors are the interface that allows the flow of electrical current between different components of a system. They are found in a wide range of applications, from power distribution networks to low current systems. The primary function of these connectors is to ensure a secure and efficient connection, preventing power loss or disruptions in the system.

In poorly designed or low-quality systems, connectors can become weak links that lead to electrical failures. Such failures can range from power interruptions to dangerous electrical fires, which can cause significant property damage or even loss of life. Therefore, investing in high-quality connectors is vital for ensuring both operational efficiency and safety in any electrical installation.

Preventing Overheating and Short Circuits

One of the most common causes of electrical failures is overheating, often caused by poor contact between connectors. When connectors are made from low-quality materials, their surface contact resistance can increase, leading to heat generation as electrical current passes through. Over time, this excessive heat can degrade the connector, causing it to melt, burn, or fail entirely. High-quality connectors, on the other hand, are designed to handle high electrical loads with minimal resistance, reducing the risk of overheating and short circuits.

Additionally, poor connectors can lead to arcing—an electrical discharge between two conductors—that can result in fires or equipment damage. Properly designed, high-quality connectors prevent arcing by ensuring tight and secure connections, thereby maintaining a continuous, safe electrical flow.

Ensuring Long-Term Durability

Electrical connectors are exposed to various environmental factors, including moisture, temperature variations, and corrosive agents. When these connectors are made from substandard materials, they are more susceptible to wear and tear. Corrosion, in particular, can degrade the quality of the connection and lead to electrical failures. For instance, in outdoor electrical systems or installations in high-humidity environments, connectors that aren’t corrosion-resistant can lead to system malfunctions.

High-quality connectors, however, are made from durable, corrosion-resistant materials such as stainless steel, brass, or special alloys. These materials ensure that the connectors retain their functionality even in harsh conditions, extending the life of the electrical system and preventing potential hazards due to component failure.

The Importance of Connector Quality in Power Systems

In large-scale power systems, such as those used in industrial facilities or power distribution networks, the reliability of every component is critical. A failure in one connector can lead to cascading system failures, resulting in outages or expensive repairs. In extreme cases, electrical failures can cause fires, electrocution hazards, or equipment damage that may require costly replacements.

For instance, power plants rely heavily on high-quality connectors for their operations, as any malfunction can have a catastrophic impact on productivity and safety. Similarly, in residential and commercial buildings, poor connectors can cause circuit failures, overloading, or even the triggering of safety mechanisms like circuit breakers, which leads to inconvenient power outages.

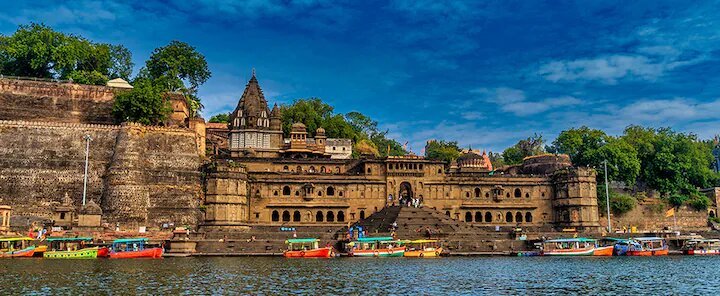

Therefore, it is crucial to ensure that connectors are properly tested and made of quality materials. For those looking for trusted electrical solutions, the Top Electrical Solution Company in Rajasthan Manikaran Enterprises, offers high-quality connectors and electrical products that ensure safety and reliability in all types of electrical installations.

Enhancing Electrical Safety with Proper Connector Installation

Proper installation of connectors is as important as using quality connectors themselves. Even the best connectors will fail if they are not installed correctly. Incorrect installation can lead to loose connections, poor contact, or even electrical shocks, which can be dangerous. It’s important to follow the manufacturer’s guidelines for installation, ensuring connectors are securely attached and properly aligned to avoid any risk of failure.

In addition to the installation, regular maintenance and inspection are necessary to ensure connectors continue to perform optimally. Regular checks can help identify early signs of wear and tear, such as corrosion, oxidation, or overheating, allowing for timely replacements before any major issues arise.

For those in need of specialized electrical systems, including Low Current System In India, it is essential to choose connectors that are specifically designed for low-current applications. These systems require connectors that are not only durable but also sensitive to smaller electrical loads. Ensuring proper connector selection and installation can make a significant difference in the safety and longevity of these systems.

Conclusion

In conclusion, the quality of connectors is critical in ensuring the safety and reliability of electrical systems. High-quality connectors prevent overheating, reduce the risk of short circuits, and ensure long-term durability, making them an essential component in any electrical installation. Whether you’re managing large-scale power systems or smaller, low-current systems, investing in quality connectors will reduce the likelihood of electrical failures and hazards. For trusted solutions and expert services, Manikaran Enterprises stands out as a leader in providing top-notch electrical products and services.