In high-risk industries, one mistake can have catastrophic consequences. That’s where Process Safety Management (PSM) becomes essential. By examining real-world case studies, industries can understand how even minor oversights in process safety can escalate into large-scale disasters. These incidents serve as critical learning points that underline the importance of having a well-structured PSM system in place. Let’s explore several such incidents that demonstrate why PSM is not a mere compliance activity but a necessity for safe operations.

Bhopal Gas Tragedy (India, 1984)

One of the most devastating industrial accidents in history, the Bhopal Gas Tragedy, is a textbook example of failed process safety measures. The leak of methyl isocyanate (MIC) from the Union Carbide plant led to the immediate death of thousands and long-term health consequences for many more.

What Went Wrong:

- Lack of maintenance and faulty safety systems.

- Inadequate training of operators.

- No proper containment or alert systems in place.

Lessons Learned:

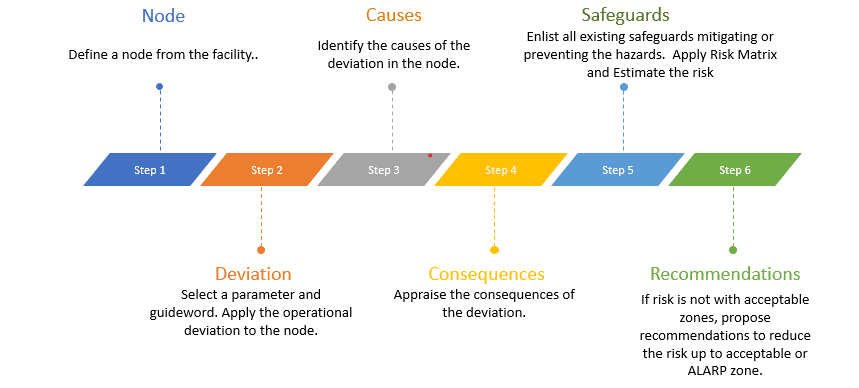

This incident became the turning point for safety reforms globally. It emphasized the importance of systematic Hazop Study, which could have identified the potential failure scenarios. Today, HAZOP is considered one of the foundational steps in designing safe chemical processes.

Texas City Refinery Explosion (USA, 2005)

At BP’s Texas City Refinery, an explosion caused by an overfilled isomerization tower and the release of flammable liquid led to 15 deaths and over 180 injuries.

What Went Wrong:

- Critical alarms and control systems were disabled.

- Lack of understanding of the process hazards.

- Inadequate Safety Audit mechanisms.

Lessons Learned:

A structured and regular safety audit could have caught the disabling of key alarms and control interlocks. This incident triggered significant changes in safety culture and raised awareness about employee training and hazard identification.

Jaipur Oil Depot Fire (India, 2009)

A fire at the Indian Oil Corporation’s depot in Jaipur lasted for over a week, claiming lives and causing environmental and economic losses.

What Went Wrong:

- Overfilling of a tank without real-time monitoring.

- Delayed emergency response.

- Poor implementation of Fire Audit practices.

Lessons Learned:

The absence of a robust fire safety protocol and audit made it impossible to detect early warning signs. The case revealed the urgency of pre-incident evaluations and proactive fire risk assessments in oil and gas storage facilities.

Formosa Plastics Explosion (USA, 2005)

In this case, an explosion at a Formosa Plastics plant in Texas resulted from a leak of vinyl chloride. Fortunately, no fatalities occurred, but the facility sustained major damage.

What Went Wrong:

- Corroded piping systems.

- Lack of preventive maintenance.

- Ignored indicators from previous near-miss incidents.

Lessons Learned:

Had a Safety Consultant evaluated the site, these corrosion-related risks could have been mitigated. This case reinforced the value of third-party evaluations and external safety expertise in identifying and closing safety gaps.

Phillips Petroleum Explosion (USA, 1989)

An explosion at Phillips Petroleum’s Houston facility killed 23 workers and injured over 100. A polyethylene reactor was being restarted when a release of highly flammable gas occurred.

What Went Wrong:

- Inadequate valve safety systems.

- Insufficient training during startup procedures.

- Weak communication during shift changes.

Lessons Learned:

This tragedy emphasized the critical need for comprehensive operator training and communication strategies. A strong Process Safety Management system could have enforced consistent procedures and avoided the error chain that led to the explosion.

Chevron Refinery Fire (USA, 2012)

The Chevron Refinery in Richmond, California, experienced a major fire due to pipe corrosion. Though no deaths occurred, it caused widespread air pollution and evacuation orders in the nearby community.

What Went Wrong:

- Corrosion was known but not addressed.

- Recommendations from previous inspections were ignored.

- Emergency response was delayed.

Lessons Learned:

This case underlines the need for active management of change and inspection follow-ups. When safety inspections and audits become routine paperwork rather than proactive interventions, the system fails. It’s another example where a credible safety review could have prevented a hazardous outcome.

Visakhapatnam Gas Leak (India, 2020)

In a chilling reminder of Bhopal, a gas leak from LG Polymers in Visakhapatnam killed 12 people and hospitalized hundreds. The incident raised numerous concerns about outdated equipment and lax safety practices.

What Went Wrong:

- Restarting operations after COVID-19 lockdown without proper checks.

- Outdated storage tanks and lack of automation.

- Absence of a clear evacuation or containment strategy.

Lessons Learned:

A comprehensive hazard identification study and real-time monitoring could have prevented this tragedy. The event highlighted the importance of emergency planning and the relevance of remote safety control systems.

Lessons That Apply Across All Industries

Across all these incidents, a few themes emerge consistently:

- Lack of foresight and preventive action.

- Ignoring early warning signs and small failures.

- Inadequate training and communication.

- Weak implementation of structured safety processes.

These are not industry-specific flaws—they are systemic issues that can appear in any sector dealing with chemicals, energy, or large-scale machinery. The implementation of thorough audits, reviews, and consultations—both internal and external—plays a pivotal role in reducing these risks.

How Case Studies Inform Future Safety Practices

Real-world incidents serve as the strongest arguments for improving workplace safety. These examples are not just reminders of past failures—they are learning tools. Organizations today rely on them to:

- Conduct risk assessments based on actual failure modes.

- Improve Standard Operating Procedures (SOPs).

- Adopt technological innovations in safety controls.

- Train employees through real-life scenario simulations.

By examining where things went wrong, companies can strengthen their PSM framework and prevent history from repeating itself.