Hazard and Operability Study, commonly referred to as HAZOP Study, is a structured and systematic technique used to identify potential hazards and operational issues in complex processes. Originally developed in the 1960s for chemical process industries, the methodology is now widely adopted across sectors such as oil and gas, pharmaceuticals, manufacturing, and energy. The aim is to improve safety and reliability by proactively assessing risks before they result in actual incidents.

This guide provides an in-depth overview of the HAZOP approach, its methodology, applications, and how it aligns with broader safety frameworks like Process Safety Management.

What Is a HAZOP Study?

A HAZOP Study is a qualitative technique that evaluates how deviations from design or operational intent can lead to undesirable consequences. It involves systematically examining every part of a process to identify what could go wrong and why. Unlike general safety reviews, HAZOP relies on guidewords—such as “more,” “less,” “as well as,” and “reverse”—to challenge assumptions and reveal vulnerabilities.

The technique is typically conducted during the design phase of a new project but is equally useful for evaluating existing systems undergoing modifications. The output of a HAZOP session includes a list of deviations, possible causes, potential consequences, and recommendations for mitigation.

Methodology: How Is a HAZOP Study Conducted?

The HAZOP process involves a multidisciplinary team, usually comprising engineers, process designers, operators, and safety professionals. A facilitator with expertise in HAZOP methodology leads the sessions. The system is broken down into nodes or sections, and each node is examined using guidewords to prompt discussions around potential deviations and their impacts.

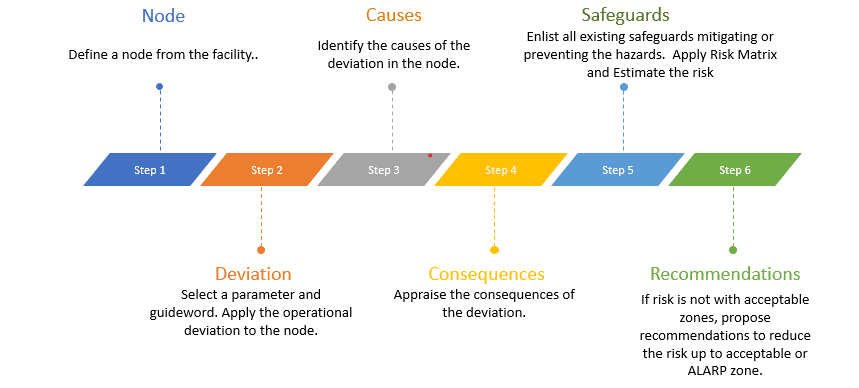

Key steps in the process include:

- Defining the scope: Identifying the boundaries and objectives of the study.

- Breaking down the process: Segmenting the process flow diagram or piping and instrumentation diagram (P&ID) into manageable nodes.

- Applying guidewords: Exploring deviations using structured language.

- Documenting findings: Recording causes, consequences, safeguards, and actions.

- Review and follow-up: Implementing and verifying recommended controls.

The success of a HAZOP depends on team diversity, session facilitation, and the depth of analysis.

Applications Across Industries

Though its roots lie in the chemical industry, the HAZOP methodology is now adapted across several high-risk sectors. In oil and gas, it supports the safe design of offshore platforms and refineries. In pharmaceuticals, it ensures compliance with strict regulatory standards. In power generation, it enhances the reliability of turbine systems and boiler operations.

A common feature across all these applications is the emphasis on system thinking. Rather than viewing components in isolation, HAZOP encourages integrated risk analysis—an essential requirement for industries governed by complex interdependencies.

HAZOP’s Relationship with Fire and Safety Audits

The insights gained from a HAZOP Study often feed directly into broader risk management activities such as Fire Audit and Safety Audit. For example, if a HAZOP session reveals that a process deviation could lead to uncontrolled thermal reactions, this becomes a focal point in fire prevention strategies and emergency planning.

Fire audits validate the adequacy of fire detection, suppression, and response systems, while safety audits evaluate overall compliance with occupational safety and health standards. Both types of audits benefit from the detailed risk identification that HAZOP provides, offering a comprehensive view of both active and passive safety systems.

Role in Process Safety Management

HAZOP plays a central role within the framework of Process Safety Management (PSM). As part of the hazard analysis element, it ensures that process hazards are methodically identified and addressed. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) and international standards like IEC 61511 also recognize HAZOP as a preferred methodology for risk assessment.

When integrated with PSM, HAZOP findings inform key components like mechanical integrity programs, operating procedures, and training requirements. This interconnectedness ensures that safety is not treated as an isolated function but as an integral aspect of operational excellence.

Involvement of a Safety Consultant

Given the technical nature and critical importance of a HAZOP, the involvement of an experienced Safety Consultant is often vital. A consultant brings domain-specific knowledge, facilitation skills, and an external perspective that enhances the quality and credibility of the study. They also help in aligning HAZOP outcomes with industry best practices and regulatory expectations.

In addition to facilitating the HAZOP sessions, a consultant often assists with training internal teams, preparing documentation, and implementing corrective measures identified during the study. Their role is particularly valuable when the organization lacks internal expertise in systematic hazard analysis.

Benefits and Limitations

The primary benefit of conducting a HAZOP is the early identification of risks, which can significantly reduce the likelihood of process failures, injuries, and environmental harm. It also improves process understanding among team members and creates a formal record of risk management decisions.

However, HAZOP does have limitations. It is time-consuming, requires skilled facilitation, and may not be suitable for all types of systems—particularly those lacking defined process flows. Additionally, its qualitative nature means that probability and risk quantification need to be supplemented by other methods.

Conclusion

A HAZOP Study is a foundational tool in the risk management arsenal of high-hazard industries. By providing a structured approach to identifying deviations, causes, and safeguards, it strengthens the safety and integrity of complex operations. When combined with fire and safety audits, supported by expert consultants, and embedded in a broader PSM framework, HAZOP offers an evidence-based path toward safer processes and operational reliability.

Whether an organization is in the design phase or seeking to improve existing processes, the insights provided by a well-executed HAZOP can serve as a cornerstone for effective hazard control and long-term resilience.